Automobile

| I | INTRODUCTION |

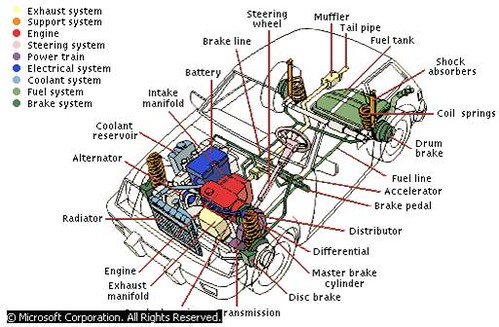

Automobile Systems

Automobiles are powered and controlled by a complicated interrelationship between several systems. This diagram shows the parts of a car with a gas engine and manual transmission (the air filter and carburetor have been removed to show the parts beneath but usually appear in the space above the intake manifold). The major systems of the automobile are the power plant, the power train, the running gear, and the control system. Each of these major categories include a number of subsystems, as shown here. The power plant includes the engine, fuel, electrical, exhaust, lubrication, and coolant systems. The power train includes the transmission and drive systems, including the clutch, differential, and drive shaft. Suspension, stabilizers, wheels, and tires are all part of the running gear, or support system. Steering and brake systems are the major components of the control system, by which the driver directs the car.

© Microsoft Corporation. All Rights Reserved.

Automobile, self-propelled vehicle used primarily on public roads but adaptable to other surfaces. Automobiles changed the world during the 20th century, particularly in the United States and other industrialized nations. From the growth of suburbs to the development of elaborate road and highway systems, the so-called horseless carriage has forever altered the modern landscape. The manufacture, sale, and servicing of automobiles have become key elements of industrial economies. But along with greater mobility and job creation, the automobile has brought noise and air pollution, and automobile accidents rank among the leading causes of death and injury throughout the world. But for better or worse, the 1900s can be called the Age of the Automobile, and cars will no doubt continue to shape our culture and economy well into the 21st century.

Automobiles are classified by size, style, number of doors, and intended use. The typical automobile, also called a car, auto, motorcar, and passenger car, has four wheels and can carry up to six people, including a driver. Larger vehicles designed to carry more passengers are called vans, minivans, omnibuses, or buses. Those used to carry cargo are called pickups or trucks, depending on their size and design. Minivans are van-style vehicles built on a passenger car frame that can usually carry up to eight passengers. Sport-utility vehicles, also known as SUVs, are more rugged than passenger cars and are designed for driving in mud or snow.

Auto manufacturing plants in 40 countries produced a total of 63.9 million vehicles, including 42.8 million passenger cars, in 2004, according to Ward’s Auto, an auto industry analyst. About 16.2 million vehicles, including 6.3 million passenger cars, were produced in North America in 2004. For information on the business of making cars, see Automobile Industry.

The automobile is built around an engine. Various systems supply the engine with fuel, cool it during operation, lubricate its moving parts, and remove exhaust gases it creates. The engine produces mechanical power that is transmitted to the automobile’s wheels through a drivetrain, which includes a transmission, one or more driveshafts, a differential gear, and axles. Suspension systems, which include springs and shock absorbers, cushion the ride and help protect the vehicle from being damaged by bumps, heavy loads, and other stresses. Wheels and tires support the vehicle on the roadway and, when rotated by powered axles, propel the vehicle forward or backward. Steering and braking systems provide control over direction and speed. An electrical system starts and operates the engine, monitors and controls many aspects of the vehicle’s operation, and powers such components as headlights and radios. Safety features such as bumpers, air bags, and seat belts help protect occupants in an accident.

| II | POWER SYSTEM |

Gasoline internal-combustion engines power most automobiles, but some engines use diesel fuel, electricity, natural gas, solar energy, or fuels derived from methanol (wood alcohol) and ethanol (grain alcohol).

Most gasoline engines work in the following way: Turning the ignition key operates a switch that sends electricity from a battery to a starter motor. The starter motor turns a disk known as a flywheel, which in turn causes the engine’s crankshaft to revolve. The rotating crankshaft causes pistons, which are solid cylinders that fit snugly inside the engine’s hollow cylinders, to move up and down. Fuel-injection systems or, in older cars, a carburetor deliver fuel vapor from the gas tank to the engine cylinders.

The pistons compress the vapor inside the cylinders. An electric current flows through a spark plug to ignite the vapor. The fuel mixture explodes, or combusts, creating hot expanding gases that push the pistons down the cylinders and cause the crankshaft to rotate. The crankshaft is now rotating via the up-and-down motion of the pistons, permitting the starter motor to disengage from the flywheel.

| A | Engine |

The basic components of an internal-combustion engine are the engine block, cylinder head, cylinders, pistons, valves, crankshaft, and camshaft. The lower part of the engine, called the engine block, houses the cylinders, pistons, and crankshaft. The components of other engine systems bolt or attach to the engine block. The block is manufactured with internal passageways for lubricants and coolant. Engine blocks are made of cast iron or aluminum alloy and formed with a set of round cylinders.

The upper part of the engine is the cylinder head. Bolted to the top of the block, it seals the tops of the cylinders. Pistons compress air and fuel against the cylinder head prior to ignition. The top of the piston forms the floor of the combustion chamber. A rod connects the bottom of the piston to the crankshaft. Lubricated bearings enable both ends of the connecting rod to pivot, transferring the piston’s vertical motion into the crankshaft’s rotational force, or torque. The pistons’ motion rotates the crankshaft at speeds ranging from about 600 to thousands of revolutions per minute (rpm), depending on how much fuel is delivered to the cylinders.

Fuel vapor enters and exhaust gases leave the combustion chamber through openings in the cylinder head controlled by valves. The typical engine valve is a metal shaft with a disk at one end fitted to block the opening. The other end of the shaft is mechanically linked to a camshaft, a round rod with odd-shaped lobes located inside the engine block or in the cylinder head. Inlet valves open to allow fuel to enter the combustion chambers. Outlet valves open to let exhaust gases out.

A gear wheel, belt, or chain links the camshaft to the crankshaft. When the crankshaft forces the camshaft to turn, lobes on the camshaft cause valves to open and close at precise moments in the engine’s cycle. When fuel vapor ignites, the intake and outlet valves close tightly to direct the force of the explosion downward on the piston.

| B | Engine Types |

The blocks in most internal-combustion engines are in-line designs or V designs. In-line designs are arranged so that the cylinders stand upright in a single line over the crankshaft. In a V design, two rows of cylinders are set at an angle to form a V. At the bottom of the V is the crankshaft. In-line configurations of six or eight cylinders require long engine compartments found more often in trucks than in cars. The V design allows the same number of cylinders to fit into a shorter, although wider, space. Another engine design that fits into shorter, shallower spaces is a horizontally opposed, or flat, arrangement in which the crankshaft lies between two rows of cylinders.

Engines become more powerful, and use more fuel, as the size and number of cylinders increase. Most modern vehicles in the United States have 4-, 6-, or 8-cylinder engines, but car engines have been designed with 1, 2, 3, 5, 12, and more cylinders.

Diesel engines, common in large trucks or buses, are similar to gasoline internal-combustion engines, but they have a different ignition system. Diesels compress air inside the cylinders with greater force than a gasoline engine does, producing temperatures hot enough to ignite the diesel fuel on contact. Some cars have rotary engines, also known as Wankel engines, which have one or more elliptical chambers in which triangular-shaped rotors, instead of pistons, rotate.

Electric motors have been used to power automobiles since the late 1800s. Electric power supplied by batteries runs the motor, which rotates a driveshaft, the shaft that transmits engine power to the axles. Commercial electric car models for specialized purposes were available in the 1980s. General Motors Corporation introduced a mass-production all-electric car in the mid-1990s.

Automobiles that combine two or more types of engines are called hybrids. A typical hybrid is an electric motor with batteries that are recharged by a generator run by a small gas- or diesel-powered engine. These hybrids are known as hybrid electric vehicles (HEVs). By relying more on electricity and less on fuel combustion, HEVs have higher fuel efficiency and emit fewer pollutants. Several automakers have experimented with hybrids.

In 1997 Toyota Motor Corporation became the first to mass-produce a hybrid vehicle, the Prius. It became available in Japan in 1997 and in North America in 2000. The first hybrid available for sale in North America, the Honda Insight, was offered by Honda Motor Co., Ltd., in 1999. Honda later introduced a hybrid version of the Honda Civic. In August 2004 the Ford Motor Company became the first U.S. automaker to release a hybrid vehicle when it began production of the Ford Escape Hybrid, the first hybrid sport- utility vehicle (SUV). The Escape Hybrid was released for the 2005 model year.

| C | Fuel Supply |

Fuel-Injection System

The fuel-injection system replaces the carburetor in most new vehicles to provide a more efficient fuel delivery system. Electronic sensors respond to varying engine speeds and driving conditions by changing the ratio of fuel to air. The sensors send a fine mist of fuel from the fuel supply through a fuel-injection nozzle into a combustion chamber, where it is mixed with air. The mixture of fuel and air triggers ignition.

© Microsoft Corporation. All Rights Reserved.

The internal-combustion engine is powered by the burning of a precise mixture of liquefied fuel and air in the cylinders’ combustion chambers. Fuel is stored in a tank until it is needed, then pumped to a carburetor or, in newer cars, to a fuel-injection system.

The carburetor controls the mixture of gas and air that travels to the engine. It mixes fuel with air at the head of a pipe, called the intake manifold, leading to the cylinders. A vacuum created by the downward strokes of pistons draws air through the carburetor and intake manifold. Inside the carburetor, the airflow transforms drops of fuel into a fine mist, or vapor. The intake manifold delivers the fuel vapor to the cylinders, where it is ignited.

All new cars produced today are equipped with fuel injection systems instead of carburetors. Fuel injectors spray carefully calibrated bursts of fuel mist into cylinders either at or near openings to the combustion chambers. Since the exact quantity of gas needed is injected into the cylinders, fuel injection is more precise, easier to adjust, and more consistent than a carburetor, delivering better efficiency, gas mileage, engine responsiveness, and pollution control. Fuel-injection systems vary widely, but most are operated or managed electronically.

High-performance automobiles are often fitted with air-compressing equipment that increases an engine’s output. By increasing the air and fuel flow to the engine, these features produce greater horsepower. Superchargers are compressors powered by the crankshaft. Turbochargers are turbine-powered compressors run by pressurized exhaust gas.

| D | Exhaust System |

The exhaust system carries exhaust gases from the engine’s combustion chamber to the atmosphere and reduces, or muffles, engine noise. Exhaust gases leave the engine in a pipe, traveling through a catalytic converter and a muffler before exiting through the tailpipe.

Chemical reactions inside the catalytic converter change most of the hazardous hydrocarbons and carbon monoxide produced by the engine into water vapor and carbon dioxide.

The conventional muffler is an enclosed metal tube packed with sound-deadening material. Most conventional mufflers are round or oval-shaped with an inlet and outlet pipe at either end. Some contain partitions to help reduce engine noise.

Car manufacturers are experimenting with an electronic muffler, which uses sensors to monitor the sound waves of the exhaust noise. The sound wave data are sent to a computer that controls speakers near the tailpipe. The system generates sound waves 180 degrees out of phase with the engine noise. The sound waves from the electronic muffler collide with the exhaust sound waves and they cancel each other out, leaving only low-level heat to emerge from the tailpipe.

| E | Cooling and Heating System |

Combustion inside an engine produces temperatures high enough to melt cast iron. A cooling system conducts this heat away from the engine’s cylinders and radiates it into the air.

In most automobiles, a liquid coolant circulates through the engine. A pump sends the coolant from the engine to a radiator, which transfers heat from the coolant to the air. In early engines, the coolant was water. In most automobiles today, the coolant is a chemical solution called antifreeze that has a higher boiling point and lower freezing point than water, making it effective in temperature extremes. Some engines are air cooled, that is, they are designed so a flow of air can reach metal fins that conduct heat away from the cylinders.

A second, smaller radiator is fitted to all modern cars. This unit uses engine heat to warm the interior of the passenger compartment and supply heat to the windshield defroster.

| III | DRIVETRAIN |

The rotational force of the engine’s crankshaft turns other shafts and gears that eventually cause the drive wheels to rotate. The various components that link the crankshaft to the drive wheels make up the drivetrain. The major parts of the drivetrain include the transmission, one or more driveshafts, differential gears, and axles.

| A | Transmission |

Automatic Transmission System

The automatic transmission is one of the key components of an automobile. Located just behind the engine, the transmission changes the speed and power ratios between the engine and the driving wheels of a vehicle.

© Microsoft Corporation. All Rights Reserved.

The transmission, also known as the gearbox, transfers power from the engine to the driveshaft. As the engine’s crankshaft rotates, combinations of transmission gears pass the energy along to a driveshaft. The driveshaft causes axles to rotate and turn the wheels. By using gears of different sizes, a transmission alters the rotational speed and torque of the engine passed along to the driveshaft. Higher gears permit the car to travel faster, while low gears provide more power for starting a car from a standstill and for climbing hills.

The transmission usually is located just behind the engine, although some automobiles were designed with a transmission mounted on the rear axle. There are three basic transmission types: manual, automatic, and continuously variable.

A manual transmission has a gearbox from which the driver selects specific gears depending on road speed and engine load. Gears are selected with a shift lever located on the floor next to the driver or on the steering column. The driver presses on the clutch to disengage the transmission from the engine to permit a change of gears. The clutch disk attaches to the transmission’s input shaft. It presses against a circular plate attached to the engine’s flywheel. When the driver presses down on the clutch pedal to shift gears, a mechanical lever called a clutch fork and a device called a throwout bearing separate the two disks. Releasing the clutch pedal presses the two disks together, transferring torque from the engine to the transmission.

An automatic transmission selects gears itself according to road conditions and the amount of load on the engine. Instead of a manual clutch, automatic transmissions use a hydraulic torque converter to transfer engine power to the transmission.

Instead of making distinct changes from one gear to the next, a continuously variable transmission uses belts and pulleys to smoothly slide the gear ratio up or down. Continuously variable transmissions appeared on machinery during the 19th century and on a few small-engine automobiles as early as 1900. The transmission keeps the engine running at its most efficient speed by more precisely matching the gear ratio to the situation. Commercial applications have been limited to small engines.

| B | Front- and Rear-Wheel Drive |

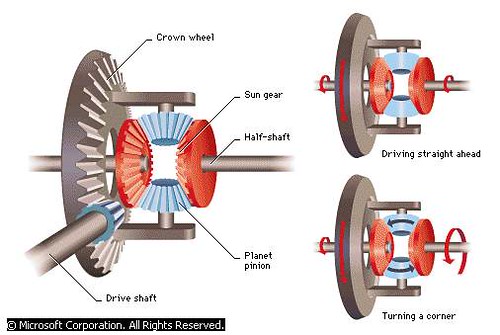

Differential

The gears of a differential allow a car's powered wheels to rotate at different speeds as the car turns around corners. The car's drive shaft rotates the crown wheel, which in turn rotates the half shafts leading to the wheels. When the car is traveling straight ahead, the planet pinions do not spin, so the crown wheel rotates both wheels at the same rate. When the car turns a corner, however, the planet pinions spin in opposite directions, allowing one wheel to slip behind and forcing the other wheel to turn faster.

© Microsoft Corporation. All Rights Reserved.

Depending on the vehicle’s design, engine power is transmitted by the transmission to the front wheels, the rear wheels, or to all four wheels. The wheels receiving power are called drive wheels: They propel the vehicle forward or backward. Most automobiles either are front-wheel or rear-wheel drive. In some vehicles, four-wheel drive is an option the driver selects for certain road conditions; others feature full-time, all-wheel drive.

The differential is a gear assembly in an axle that enables each powered wheel to turn at different speeds when the vehicle makes a turn. The driveshaft connects the transmission’s output shaft to a differential gear in the axle. Universal joints at both ends of the driveshaft allow it to rotate as the axles move up and down over the road surface.

In rear-wheel drive, the driveshaft runs under the car to a differential gear at the rear axle. In front-wheel drive, the differential is on the front axle and the connections to the transmission are much shorter. Four-wheel-drive vehicles have drive shafts and differentials for both axles.

| IV | SUPPORT SYSTEMS |

Automobiles would deliver jolting rides, especially on unpaved roads, without a system of shock absorbers and other devices to protect the auto body and passenger compartment from severe bumps and bounces.

| A | Suspension System |

The suspension system, part of the undercarriage of an automobile, contains springs that move up and down to absorb bumps and vibrations. In one type of suspension system, a long tube, or strut, has a shock absorber built into its center section. Shock absorbers control, or dampen, the sudden loading and unloading of suspension springs to reduce wheel bounce and the shock transferred from the road wheels to the body. One shock absorber is installed at each wheel. Modern shock absorbers have a telescoping design and use oil, gas, and air, or a combination to absorb energy.

Luxury sedans generally have a soft suspension for comfortable riding. Sports cars and sport-utility vehicles have firmer suspensions to improve cornering ability and control over rough terrain.

Older automobiles were equipped with one-piece front axles attached to the frame with semielliptic leaf springs, much like the arrangement on horse-drawn buggies. Front wheels on modern cars roll independently of each other on half-shafts instead of on a common axle. Each wheel has its own axle and suspension supports, so the shock of one wheel hitting a bump is not transferred across a common axle to the other wheel or the rest of the car. Many rear-axle suspensions for automobiles and heavier vehicles use rigid axles with coil or leaf springs. However, advanced passenger cars, luxury sedans, and sports cars feature independent rear-wheel suspension systems.

Active suspensions are computer-controlled adjustments of the downward force of each wheel as the vehicle corners or rides over uneven terrain. Sensors, a pump, and hydraulic cylinders, all monitored and controlled by computer, enable the vehicle to lean into corners and compensate for the dips and dives that accompany emergency stops and rapid acceleration.

| B | Wheels and Tires |

Wheels support the vehicle’s weight and transfer torque to the tires from the drivetrain and braking systems. Automobile wheels generally are made of steel or aluminum. Aluminum wheels are lighter, more impact absorbent, and more expensive.

Pneumatic (air-filled) rubber tires, first patented in 1845, fit on the outside rims of the wheels. Tires help smooth out the ride and provide the automobile’s only contact with the road, so traction and strength are primary requirements. Tire treads come in several varieties to match driving conditions.

| V | CONTROL SYSTEMS |

A driver controls the automobile’s motion by keeping the wheels pointed in the desired direction, and by stopping or slowing the speed at which the wheels rotate. These controls are made possible by the steering and braking systems. In addition, the driver controls the vehicle’s speed with the transmission and the gas pedal, which adjusts the amount of fuel fed to the engine.

| A | Steering |

Automobiles are steered by turning the front wheels, although a few automobile types have all-wheel steering. Most steering systems link the front wheels together by means of a tie-rod. The tie-rod insures that the turning of one wheel is matched by a corresponding turn in the other.

When a driver turns the steering wheel, the mechanical action rotates a steering shaft inside the steering column. Depending on the steering mechanism, gears or other devices convert the rotating motion of the steering wheel into a horizontal force that turns the wheels.

Manual steering relies only on the force exerted by the driver to turn the wheels. Conventional power steering uses hydraulic pressure, operated by the pressure or movement of a liquid, to augment that force, requiring less effort by the driver. Electric power steering uses an electric motor instead of hydraulic pressure.

| B | Brakes |

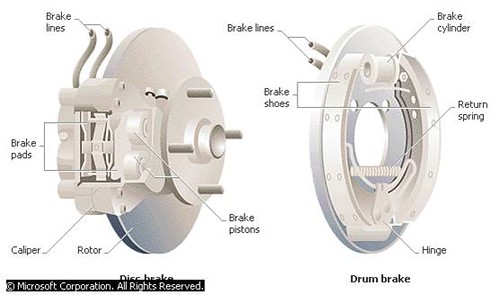

Disc and Drum Brakes

Disc and drum brakes create friction to slow the wheels of a motor vehicle. When a driver presses on the brake pedal of a vehicle, brake lines filled with fluid transmit the force to the brakes. In a disc brake, the fluid pushes the brake pads in the caliper against the rotor, slowing the wheel. In a drum brake, the fluid pushes small pistons in the brake cylinder against the hinged brake shoes. The shoes pivot outward and press against a drum attached to the wheel to slow the wheel.

© Microsoft Corporation. All Rights Reserved.

Brakes enable the driver to slow or stop the moving vehicle. The first automobile brakes were much like those on horse-drawn wagons. By pulling a lever, the driver pressed a block of wood, leather, or metal, known as the shoe, against the wheel rims. With sufficient pressure, friction between the wheel and the brake shoe caused the vehicle to slow down or stop. Another method was to use a lever to clamp a strap or brake shoes tightly around the driveshaft.

A brake system with shoes that pressed against the inside of a drum fitted to the wheel, called drum brakes, appeared in 1903. Since the drum and wheel rotate together, friction applied by the shoes inside the drum slowed or stopped the wheel. Cotton and leather shoe coverings, or linings, were replaced by asbestos after 1908, greatly extending the life of the brake mechanism. Hydraulically assisted braking was introduced in the 1920s. Disk brakes, in which friction pads clamp down on both sides of a disk attached to the axle, were in use by the 1950s.

An antilock braking system (ABS) uses a computer, sensors, and a hydraulic pump to stop the automobile’s forward motion without locking the wheels and putting the vehicle into a skid. Introduced in the 1980s, ABS helps the driver maintain better control over the car during emergency stops and while braking on slippery surfaces.

Automobiles are also equipped with a hand-operated brake used for emergencies and to securely park the car, especially on uneven terrain. Pulling on a lever or pushing down on a foot pedal sets the brake.

| VI | ELECTRICAL SYSTEM |

The automobile depends on electricity for fuel ignition, headlights, turn signals, horn, radio, windshield wipers, and other accessories. A battery and an alternator supply electricity. The battery stores electricity for starting the car. The alternator generates electric current while the engine is running, recharging the battery and powering the rest of the car’s electrical needs.

Early automotive electrical systems ran on 6 volts, but 12 volts became standard after World War II (1939-1945) to operate the growing number of electrical accessories. Eventually, 24- or 48-volt systems may become the standard as more computers and electronics are built into automobiles.

| A | Ignition System |

Ignition System

The ignition system delivers voltage to ignite the fuel in the automotive vehicle. When the ignition switch is turned on, low-voltage electric current flows from the battery to the coil, which converts the current to high-voltage. The current then flows to the distributor, which delivers it to each of the spark plugs. The spark plugs send an igniting spark to the fuel/air mixture in the combustion chambers.

© Microsoft Corporation. All Rights Reserved.

The ignition system supplies high-voltage current to spark plugs to ignite fuel vapor in the cylinders. There are many variations, but all gasoline-engine ignition systems draw electric current from the battery, significantly increase the current’s voltage, then deliver it to spark plugs that project into the combustion chambers. An electric arc between two electrodes at the bottom of the spark plug ignites the fuel vapor.

In older vehicles, a distributor, which is an electrical switching device, routes high-voltage current to the spark plugs. The distributor’s housing contains a switch called the breaker points. A rotating shaft in the distributor causes the switch to open and close, interrupting the supply of low-voltage current to a transformer called a coil. The coil uses electromagnetic induction (see Electricity: Electromagnetism) to convert interruptions of the 12-volt current into surges of 20,000 volts or more. This high-voltage current passes back to the distributor, which mechanically routes it through wires to spark plugs, producing a spark that ignites the gas vapor in the cylinders. A condenser absorbs excess current and protects the breaker points from damage by the high-voltage surge. The distributor and other devices control the timing of the spark-plug discharges.

In modern ignition systems, the distributor, coil, points, and condenser have been replaced by solid-state electronics controlled by a computer. A computer controls the ignition system and adjusts it to provide maximum efficiency in a variety of driving conditions.

| VII | SAFETY FEATURES |

Manufacturers continue to build lighter vehicles with improved structural rigidity and ability to protect the driver and passengers during collisions.

Bumpers evolved as rails or bars to protect the front and rear of the car’s body from damage in minor collisions. Over the years, bumpers became stylish and, in some cases, not strong enough to survive minor collisions without expensive repairs. Eventually, government regulations required bumpers designed to withstand low-speed collisions with less damage. Some bumpers can withstand 4-km/h (2.5-mph) collisions with no damage, while others can withstand 8-km/h (5-mph) collisions with no damage.

Modern vehicles feature crumple zones, portions of the automobile designed to absorb forces that otherwise would be transmitted to the passenger compartment. Passenger compartments on many vehicles also have reinforced roll bar structures in the roof, in case the vehicle overturns, and protective beams in the doors to help protect passengers from side impacts.

Seat belt and upper-body restraints that relax to permit comfort but tighten automatically during an impact are now common. Some car models are equipped with shoulder-restraint belts that slide into position automatically when the car’s doors close.

An air bag is a high-speed inflation device hidden in the hub of the steering wheel or in the dash on the passenger’s side. Some automobiles have side-impact air bags, located in doors or seats. At impact, the bag inflates almost instantaneously. The inflated bag creates a cushion between the occupant and the vehicle’s interior. Air bags first appeared in the mid-1970s, available as an optional accessory. Today they are installed on all new passenger cars sold in the United States.

Air bags inflate with great force, which occasionally endangers a child or infant passenger. Some newer automobile models are equipped with switches to disable the passenger-side air bags when a child or infant is traveling in the passenger seat. Automakers continue to research ways to make air-bag systems less dangerous for frail and small passengers, yet effective in collisions.

| VIII | HISTORY |

Horseless Carriage

The original horseless carriage was introduced in 1893 by brothers Charles and Frank Duryea. It was America’s first internal-combustion motor car, and it was followed by Henry Ford’s first experimental car that same year.

THE BETTMANN ARCHIVE

The history of the automobile actually began about 4,000 years ago when the first wheel was used for transportation in India. In the early 15th century the Portuguese arrived in China and the interaction of the two cultures led to a variety of new technologies, including the creation of a wheel that turned under its own power. By the 1600s small steam-powered engine models had been developed, but it was another century before a full-sized engine-powered vehicle was created.

In 1769 French Army officer Captain Nicolas-Joseph Cugnot built what has been called the first automobile. Cugnot’s three-wheeled, steam-powered vehicle carried four persons. Designed to move artillery pieces, it had a top speed of a little more than 3.2 km/h (2 mph) and had to stop every 20 minutes to build up a fresh head of steam.

As early as 1801 successful but very heavy steam automobiles were introduced in England. Laws barred them from public roads and forced their owners to run them like trains on private tracks. In 1802 a steam-powered coach designed by British engineer Richard Trevithick journeyed more than 160 km (100 mi) from Cornwall to London. Steam power caught the attention of other vehicle builders. In 1804 American inventor Oliver Evans built a steam-powered vehicle in Chicago, Illinois. French engineer Onésiphore Pecqueur built one in 1828.

British inventor Walter Handcock built a series of steam carriages in the mid-1830s that were used for the first omnibus service in London. By the mid-1800s England had an extensive network of steam coach lines. Horse-drawn stagecoach companies and the new railroad companies pressured the British Parliament to approve heavy tolls on steam-powered road vehicles. The tolls quickly drove the steam coach operators out of business.

During the early 20th century steam cars were popular in the United States. Most famous was the Stanley Steamer, built by American twin brothers Freelan and Francis Stanley. A Stanley Steamer established a world land speed record in 1906 of 205.44 km/h (121.573 mph). Manufacturers produced about 125 models of steam-powered automobiles, including the Stanley, until 1932.

| A | Internal-Combustion Engine |

Development of lighter steam cars during the 19th century coincided with major developments in engines that ran on gasoline or other fuels. Because the newer engines burned fuel in cylinders inside the engine, they were called internal-combustion engines.

In 1860 French inventor Jean-Joseph-Étienne Lenoir patented a one-cylinder engine that used kerosene for fuel. Two years later, a vehicle powered by Lenoir’s engine reached a top speed of about 6.4 km/h (about 4 mph). In 1864 Austrian inventor Siegfried Marcus built and drove a carriage propelled by a two-cylinder gasoline engine. American George Brayton patented an internal-combustion engine that was displayed at the 1876 Centennial Exhibition in Philadelphia, Pennsylvania.

In 1876 German engineer Nikolaus August Otto built a four-stroke gas engine, the most direct ancestor to today’s automobile engines. In a four-stroke engine the pistons move down to draw fuel vapor into the cylinder during stroke one; in stroke two, the pistons move up to compress the vapor; in stroke three the vapor explodes and the hot gases push the pistons down the cylinders; and in stroke four the pistons move up to push exhaust gases out of the cylinders. Engines with two or more cylinders are designed so combustion occurs in one cylinder after the other instead of in all at once. Two-stroke engines accomplish the same steps, but less efficiently and with more exhaust emissions.

Automobile manufacturing began in earnest in Europe by the late 1880s. German engineer Gottlieb Daimler and German inventor Wilhelm Maybach mounted a gasoline-powered engine onto a bicycle, creating a motorcycle, in 1885. In 1887 they manufactured their first car, which included a steering tiller and a four-speed gearbox. Another German engineer, Karl Benz, produced his first gasoline car in 1886. In 1890 Daimler and Maybach started a successful car manufacturing company, The Daimler Motor Company, which eventually merged with Benz’s manufacturing firm in 1926 to create Daimler-Benz. The joint company makes cars today under the Mercedes-Benz nameplate (see DaimlerChrysler AG).

In France, a company called Panhard-Levassor began making cars in 1894 using Daimler’s patents. Instead of installing the engine under the seats, as other car designers had done, the company introduced the design of a front-mounted engine under the hood. Panhard-Levassor also introduced a clutch and gears, and separate construction of the chassis, or underlying structure of the car, and the car body. The company’s first model was a gasoline-powered buggy steered by a tiller.

French bicycle manufacturer Armand Peugeot saw the Panhard-Levassor car and designed an automobile using a similar Daimler engine. In 1891 this first Peugeot automobile paced a 1,046-km (650-mi) professional bicycle race between Paris and Brest. Other French automobile manufacturers opened shop in the late 1800s, including Renault. In Italy, Fiat (Fabbrica Italiana Automobili di Torino) began building cars in 1899.

American automobile builders were not far behind. Brothers Charles Edgar Duryea and James Frank Duryea built several gas-powered vehicles between 1893 and 1895. The first Duryea, a one-cylinder, four-horsepower model, looked much like a Panhard-Levassor model. In 1893 American industrialist Henry Ford built an internal-combustion engine from plans he saw in a magazine. In 1896 he used an engine to power a vehicle mounted on bicycle wheels and steered by a tiller.

| B | Early Electric Cars |

For a few decades in the 1800s, electric engines enjoyed great popularity because they were quiet and ran at slow speeds that were less likely to scare horses and people. By 1899 an electric car designed and driven by Belgian inventor Camille Jenatzy set a record of 105.8810 km/h (65.79 mph).

Early electric cars featured a large bank of storage batteries under the hood. Heavy cables connected the batteries to a motor between the front and rear axles. Most electric cars had top speeds of 48 km/h (30 mph), but could go only 80 km (50 mi) before their batteries needed recharging. Electric automobiles were manufactured in quantity in the United States until 1930.

| IX | AUTOMOBILES IN THE 20TH CENTURY |

For many years after the introduction of automobiles, three kinds of power sources were in common use: steam engines, gasoline engines, and electric motors. In 1900 more than 2,300 automobiles were registered in New York City; Boston, Massachusetts; and Chicago, Illinois. Of these, 1,170 were steam cars, 800 were electric cars, and only 400 were gasoline cars. Gasoline-powered engines eventually became the nearly universal choice for automobiles because they allowed longer trips and faster speeds than engines powered by steam or electricity.

But development of gasoline cars in the early 1900s was hindered in the United States by legal battles over a patent obtained by New York lawyer George B. Selden. Selden saw a gasoline engine at the Philadelphia Centennial Exposition in 1876. He then designed a similar one and obtained a broad patent that for many years was interpreted to apply to all gasoline engines for automobiles. Although Selden did not manufacture engines or automobiles, he collected royalties from those who did.

Henry Ford believed Selden’s patent was invalid. Selden sued when Ford refused to pay royalties for Ford-manufactured engines. After eight years of court battles, the courts ruled in 1911 that Selden’s patent applied only to two-stroke engines. Ford and most other manufacturers were using four-stroke engines, so Selden could not charge them royalties.

Improvements in the operating and riding qualities of gasoline automobiles developed quickly after 1900. The 1902 Locomobile was the first American car with a four-cylinder, water-cooled, front-mounted gasoline engine, very similar in design to most cars today. Built-in baggage compartments appeared in 1906, along with weather resistant tops and side curtains. An electric self-starter was introduced in 1911 to replace the hand crank used to start the engine turning. Electric headlights were introduced at about the same time.

Most automobiles at the turn of the 20th century appeared more or less like horseless carriages. In 1906 gasoline-powered cars were produced that had a style all their own. In these new models, a hood covered the front-mounted engine. Two kerosene or acetylene lamps mounted to the front served as headlights. Cars had fenders that covered the wheels and step-up platforms called running boards, which helped passengers get in and out of the vehicle. The passenger compartment was behind the engine. Although drivers of horse-drawn vehicles usually sat on the right, automotive steering wheels were on the left in the United States.

In 1903 Henry Ford incorporated the Ford Motor Company, which introduced its first automobile, the Model A, in that same year. It closely resembled the 1903 Cadillac, which was hardly surprising since Ford had designed cars the previous year for the Cadillac Motor Car Company. Ford’s company rolled out new car models each year, and each model was named with a letter of the alphabet. By 1907, when models R and S appeared, Ford’s share of the domestic automobile market had soared to 35 percent.

Ford’s famous Model T debuted in 1908 but was called a 1909 Ford. Ford built 17,771 Model T’s and offered nine body styles. Popularly known as the Tin Lizzy, the Model T became one of the biggest-selling automobiles of all time. Ford sold more than 15 million before stopping production of the model in 1927. The innovative assembly-line method used by the company to build its cars was widely adopted in the automobile industry.

By 1920 more than 8 million Americans owned cars. Major reasons for the surge in automobile ownership were Ford’s Model T, the assembly-line method of building it, and the affordability of cars for the ordinary wage earner.

Improvements in engine-powered cars during the 1920s contributed to their popularity: synchromesh transmissions for easier gear shifting; four-wheel hydraulic brake systems; improved carburetors; shatterproof glass; balloon tires; heaters; and mechanically operated windshield wipers.

From 1930 to 1937, automobile engines and bodies became large and luxurious. Many 12- and 16-cylinder cars were built. Independent front suspension, which made the big cars more comfortable, appeared in 1933. Also introduced during the 1930s were stronger, more reliable braking systems, and higher-compression engines, which developed more horsepower. Mercedes introduced the world’s first diesel car in 1936. Automobiles on both sides of the Atlantic were styled with gracious proportions, long hoods, and pontoon-shaped fenders. Creative artistry merged with industrial design to produce appealing, aerodynamic automobiles.

Some of the first vehicles to fully incorporate the fender into the bodywork came along just after World War II, but the majority of designs still had separate fenders with pontoon shapes holding headlight assemblies. Three companies, Ford, Nash, and Hudson Motor Car Company, offered postwar designs that merged fenders into the bodywork. The 1949 Ford was a landmark in this respect, and its new styling was so well accepted the car continued in production virtually unchanged for three years, selling more than 3 million. During the 1940s, sealed-beam headlights, tubeless tires, and the automatic transmission were introduced.

Two schools of styling emerged in the 1950s, one on each side of the Atlantic. The Europeans continued to produce small, light cars weighing less than 1,300 kg (2,800 lb). European sports cars of that era featured hand-fashioned aluminum bodies over a steel chassis and framework.

In America, automobile designers borrowed features for their cars that were normally found on aircraft and ships, including tailfins and portholes. Automobiles were produced that had more space, more power, and smoother riding capability. Introduction of power steering and power brakes made bigger cars easier to handle. The Buick Motor Car Company, Olds Motor Vehicle Company (Oldsmobile), Cadillac Automobile Company, and Ford all built enormous cars, some weighing as much as 2,495 kg (5,500 lb).

The first import by German manufacturer Volkswagen AG, advertised as the Beetle, arrived in the United States in 1949. Only two were sold that year, but American consumers soon began buying the Beetle and other small imports by the thousands. That prompted a downsizing of some American-made vehicles. The first American car called a compact was the Nash Rambler. Introduced in 1950, it did not attract buyers on a large scale until 1958. More compacts, smaller in overall size than a standard car but with virtually the same interior body dimensions, emerged from the factories of many major manufacturers. The first Japanese imports, 16 compact trucks, arrived in the United States in 1956.

In the 1950s new automotive features were introduced, including air conditioning and electrically operated car windows and seat adjusters. Manufacturers changed from the 6-volt to the 12-volt ignition system, which gave better engine performance and more reliable operation of the growing number of electrical accessories.

By 1960 sales of foreign and domestic compacts accounted for about one-third of all passenger cars sold in the United States. American cars were built smaller, but with increased engine size and horsepower. Heating and ventilating systems became standard equipment on even the least expensive models. Automatic transmissions, power brakes, and power steering became widespread. Styling sometimes prevailed over practicality—some cars were built in which the engines had to be lifted to allow simple service operations, like changing the spark plugs. Back seats were designed with no legroom.

In the 1970s American manufacturers continued to offer smaller, lighter models in addition to the bigger sedans that led their product lines, but Japanese and European compacts continued to sell well. Catalytic converters were introduced to help reduce exhaust emissions.

During this period, the auto industry was hurt by the energy crisis, created when the Organization of Petroleum Exporting Countries (OPEC), a cartel of oil-producing countries, cut back on sales to other countries. The price of crude oil skyrocketed, driving up the price of gasoline. Large cars were getting as little as 8 miles per gallon (mpg), while imported compacts were getting as much as 35 mpg. More buyers chose the smaller, more fuel-efficient imports.

Digital speedometers and electronic prompts to service parts of the vehicle appeared in the 1980s. Japanese manufacturers opened plants in the United States. At the same time, sporty cars and family minivans surged in popularity.

Advances in automobile technology in the 1980s included better engine control and the use of innovative types of fuel. In 1981 Bayerische Motoren Werke AG (BMW) introduced an on-board computer to monitor engine performance. A solar-powered vehicle, SunRaycer, traveled 3,000 km (1,864 mi) in Australia in six days.

| X | NEW TECHNOLOGIES |

| A | Antipollution Strategies |

Pollution-control laws adopted at the beginning of the 1990s in some of the United States and in Europe called for automobiles that produced better gas mileage with lower emissions. The California Air Resources Board required companies with the largest market shares to begin selling vehicles that were pollution free—in other words, electric. In 1996 General Motors became the first to begin selling an all-electric car, the EV1, to California buyers. The all-electric cars introduced so far have been limited by low range, long recharges, and weak consumer interest.

Engines that run on hydrogen have been tested. Hydrogen combustion produces only a trace of harmful emissions, no carbon dioxide, and a water-vapor by-product. However, technical problems related to the gas’s density and flammability remain to be solved.

Diesel engines burn fuel more efficiently, and produce fewer pollutants, but they are noisy. Popular in trucks and heavy vehicles, diesel engines are only a small portion of the automobile market. A redesigned, quieter diesel engine introduced by Volkswagen in 1996 may pave the way for more diesels, and less pollution, in passenger cars.

| B | Hybrid-Electric Vehicles (HEVs) |

While some developers searched for additional alternatives, others investigated ways to combine electricity with liquid fuels to produce low-emissions power systems. The hybrid-electric vehicle (HEV) uses both an electric motor or motors and a gasoline or diesel engine that charges the batteries in order to extend the distance that the vehicle can travel without having to recharge the batteries. An HEV at a stoplight typically sits silent, burning no fuel and making no pollution, if the batteries are sufficiently charged. If driven slowly, as in heavy traffic, the vehicle might move only on electric power. Only when more power is demanded for acceleration or to move a heavy load, does the gasoline or diesel engine come into play.

Two automobiles with such hybrid engines, the Toyota Prius and the Honda Insight, became available in the late 1990s. The Prius hit automobile showrooms in Japan in 1997, selling 30,000 models in its first two years of production. The Prius became available for sale in North America in 2000. The Honda Insight debuted in North America in late 1999. Both vehicles promised to double the fuel efficiency of conventional gasoline-powered cars while significantly reducing toxic emissions. The Ford Motor Company introduced the first U.S.-made hybrid when it began production for the Ford Escape Hybrid in August 2004. The 2005 model year Escape was also the first hybrid in the sport-utility vehicle (SUV) category. Electric Car.

| C | Computers and Navigation Devices |

Computer control of automobile systems increased dramatically during the 1990s. The central processing unit (CPU) in modern engines manages overall engine performance. Microprocessors regulating other systems share data with the CPU. Computers manage fuel and air mixture ratios, ignition timing, and exhaust-emission levels. They adjust the antilock braking and traction control systems. In many models, computers also control the air conditioning and heating, the sound system, and the information displayed in the vehicle’s dashboard.

Expanded use of computer technology, development of stronger and lighter materials, and research on pollution control will produce better, “smarter” automobiles. In the 1980s the notion that a car would “talk” to its driver was science fiction; by the 1990s it had become reality.

Onboard navigation was one of the new automotive technologies in the 1990s. By using the satellite-aided global positioning system (GPS), a computer in the automobile can pinpoint the vehicle’s location within a few meters. The onboard navigation system uses an electronic compass, digitized maps, and a display screen showing where the vehicle is relative to the destination the driver wants to reach. After being told the destination, the computer locates it and directs the driver to it, offering alternative routes if needed.

Some cars now come equipped with GPS locator beacons, enabling a GPS system operator to locate the vehicle, map its location, and if necessary, direct repair or emergency workers to the scene.

Cars equipped with computers and cellular telephones can link to the Internet to obtain constantly updated traffic reports, weather information, route directions, and other data. Future built-in computer systems may be used to automatically obtain business information over the Internet and manage personal affairs while the vehicle’s owner is driving.

| D | Other Improvements |

During the 1980s and 1990s, manufacturers trimmed 450 kg (1,000 lb) from the weight of the typical car by making cars smaller. Less weight, coupled with more efficient engines, doubled the gas mileage obtained by the average new car between 1974 and 1995. Further reductions in vehicle size are not practical, so the emphasis has shifted to using lighter materials, such as plastics, aluminum alloys, and carbon composites, in the engine and the rest of the vehicle.

Looking ahead, engineers are devising ways to reduce driver errors and poor driving habits. Systems already exist in some locales to prevent intoxicated drivers from starting their vehicles. The technology may be expanded to new vehicles. Anticollision systems with sensors and warning signals are being developed. In some, the car’s brakes automatically slow the vehicle if it is following another vehicle too closely. New infrared sensors or radar systems may warn drivers when another vehicle is in their “blind spot.”

Gas-Electric Hybrids

The Toyota Prius, top, a four-seat hybrid electric vehicle (HEV), was the first HEV to be marketed when Toyota introduced it in Japan in 1997. The Honda Insight, bottom, a two-seat HEV, followed in 1999 when it was sold in both Japan and the United States. The Prius had its U.S. debut in 2000.

Marty Lederhandler and Kim D. Johnson/AP Wide World Photos, Inc.

Contributed By:

David Fetherston

Microsoft ® Encarta ® 2007. © 1993-2006 Microsoft Corporation. All rights reserved.

Comments

Post a Comment

Bagi Yang Mau Memberi Komentar Tinggal Poskan Komentar di Kotak Komentar..

Yang tak punya url bisa dikosongkan..

tapi tolong di diisi oke Name-nya

Komentar anda saya tunggu :d